For professional buyers, a COA is not just “a lab paper.” It is a decision document: it tells procurement, QA, and compliance teams whether a lot is suitable for your channel and whether it matches your internal specification. When COAs are aligned early, quotations move faster and fewer surprises occur at shipment stage.

1) What a honey COA typically includes

COA formats vary, but strong COAs generally include the items below. If any of these are missing, buyers often request a revised version for internal traceability.

- Product identification: type/variety, pack or bulk format, and intended use (retail/foodservice/industrial).

- Lot/batch ID: essential for traceability and release decisions.

- Production/packing date: and sometimes sampling date (especially when labs test a retained sample).

- Test list: parameters tested, with units and pass/fail or spec limits.

- Methods: test methods or references (e.g., internal method codes or recognized method references).

- Laboratory identity: in-house or third-party; lab name and location are commonly requested.

- Authorization: signature or approval, and document revision/date.

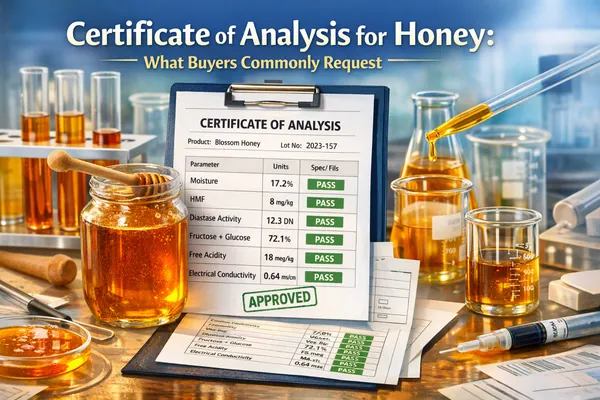

2) Core honey parameters buyers commonly request

The “core set” below is a practical baseline requested by many professional buyers. Exact limits depend on destination market, buyer policy, and intended use.

| Parameter | Why buyers care | Practical note |

|---|---|---|

| Moisture | Stability and fermentation risk | Often one of the first “go/no-go” checks for many QA teams. |

| HMF | Heat/aging indicator; handling control | Requested frequently for export and branded programs. |

| Diastase activity | Freshness/handling indicator (context-dependent) | Often reviewed alongside HMF rather than alone. |

| Electrical conductivity | Helps characterize honey type and profile | Common in spec packs for varietal alignment and consistency. |

| Free acidity | Quality and stability indicator | Often used as part of an overall quality check. |

| Fructose + glucose | Sugar profile baseline | Used for specification conformance; may influence crystallization expectations. |

| Insoluble matter | Clarity and filtration control | Especially relevant for retail presentation and fine filtration expectations. |

3) How COA and documentation needs differ by channel

The most common misalignment happens when retail-style documentation is used for industrial buyers (or vice versa). Use channel context to decide what “good documentation” looks like.

| Channel | Documentation emphasis | Typical add-ons |

|---|---|---|

| Retail (branded/private label) | Consistent spec pack, label alignment, lot traceability | Artwork/label review, allergen statements, shelf-life statement, pallet configuration. |

| Foodservice | Pack integrity, convenience, repeatability across reorders | Portion pack specs, leakage controls, carton strength, serving format compliance. |

| Industrial/ingredient | Process performance, broader risk screening, tight release criteria | Custom spec limits, additional screening aligned to buyer risk assessment, viscosity/handling notes. |

4) COA vs specification sheet vs “document pack”

Buyers often request a “document pack,” which may include multiple files. Clarify internally what each document does:

- COA (lot-specific): test results for the lot being shipped.

- Specification sheet (product-level): target ranges/limits and general product description.

- Traceability info: batch codes, production/packing dates, and sometimes pallet marks.

- Commercial documents: packing list, invoice, and shipment markings (handled in logistics workflow).

5) How to request a COA effectively (to avoid delays)

The fastest approach is to tell the supplier exactly which parameters you need and when you need them. Many buyers also specify whether a third-party lab is required or whether in-house testing is acceptable.

- Specify the lot timing: “COA for the shipment lot prior to dispatch.”

- Ask who issues it: in-house QA vs third-party lab; request lab name.

- Confirm units and method references: avoid mismatched units that create internal rejection.

- Require batch ID alignment: COA lot ID must match packing list / drum or carton marks.

- Set review window: “Send COA at least X days before shipment for approval.”

6) Copy/paste RFQ checklist for COA and documentation

Use the template below to speed up internal alignment and supplier responses. This is written to be practical for procurement emails and RFQ forms.

7) Common documentation mistakes that slow approvals

Procurement teams often lose time due to avoidable issues. These are frequent causes of “please revise and resend” loops:

- COA is not lot-specific (it looks like a generic spec sheet).

- Batch/lot ID does not match shipment markings or the packing list.

- Units are missing or inconsistent across lots.

- Parameters are listed without spec limits or pass/fail indication (when buyer requires it).

- Document date/revision is missing (harder for QA to archive).