For importers and distributors, honey success in Africa typically comes down to matching the offer to the route-to-market: mainstream retail, wholesale/traditional trade, foodservice, or ingredient supply. Each route drives different packaging, pricing, and replenishment behavior.

1) Channel realities: where honey moves fastest

- Mainstream retail: favors consistent everyday SKUs, clean labeling, and stable supply.

- Traditional trade / wholesalers: emphasizes price points, durable packs, and case efficiency.

- Hotels & cafes: often prioritize portion cups or squeeze formats for hygiene and portion control.

- Industrial / ingredient: buys bulk formats aligned to production schedules and handling equipment.

2) Portfolio planning: start simple, then expand

A common go-to-market approach is a two-tier portfolio: a high-turn core honey for volume plus a differentiation SKU for margin and brand story. Once distribution stabilizes, add premium or monofloral lines based on proven demand.

| Tier | Role | Typical positioning | Common pack focus |

|---|---|---|---|

| Core | Volume driver | Everyday sweetener, family use | Durable, cost-efficient formats; repeatable specs |

| Premium | Margin + differentiation | Origin/story, gifting, specialty | Stronger shelf presence; premium packaging where viable |

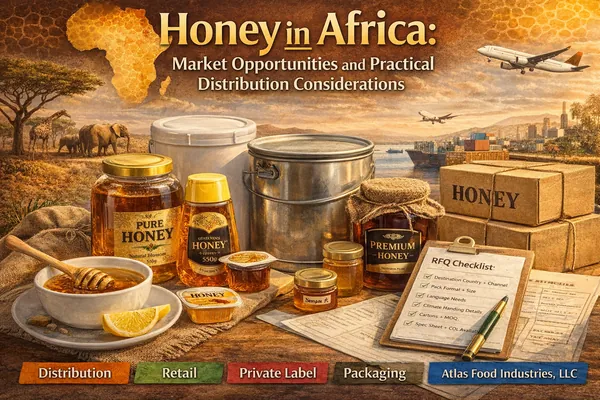

3) Packaging choices that fit distribution constraints

Packaging selection is often the “hidden lever” for distribution performance. Long distances, warm climates, and multi-step handling reward robust packs, leak resistance, and efficient case/pallet geometry.

- Plastic jars / PET: often used for durability and lower breakage risk in extended distribution chains.

- Squeeze formats: strong for fast dosing and reduced mess; a practical fit for foodservice and some retail segments.

- Glass jars: premium positioning and gifting; ensure protective secondary packaging for transit.

- Portion packs: hotels/airlines/catering; supports hygiene and predictable cost-per-serving.

4) Logistics and replenishment: reduce friction early

- Plan around port + inland distribution: lead time is not only production—local clearance and inland transport can dominate.

- Keep case counts consistent: stable carton configuration helps forecasting and warehouse slotting.

- Document alignment: provide destination and compliance needs early to prevent delays at clearance.